By Jeff Goldblatt and Katie Felver

Widely accepted by the global scientific community, our planet is approaching a “tipping point” of irreversible climate change. We are seeing this evidence with the ever-increasing intensity and frequency of natural disasters having catastrophic impacts. Scientific research has linked carbon emissions as a fundamental catalyst of climate change. While there are metrics to help set goals towards carbon reduction in many industries, including our own, one thing is for certain – we need to reduce the amount of carbon being emitted into the atmosphere as quickly as possible.

DEFINING OPERATIONAL AND EMBODIED CARBONS

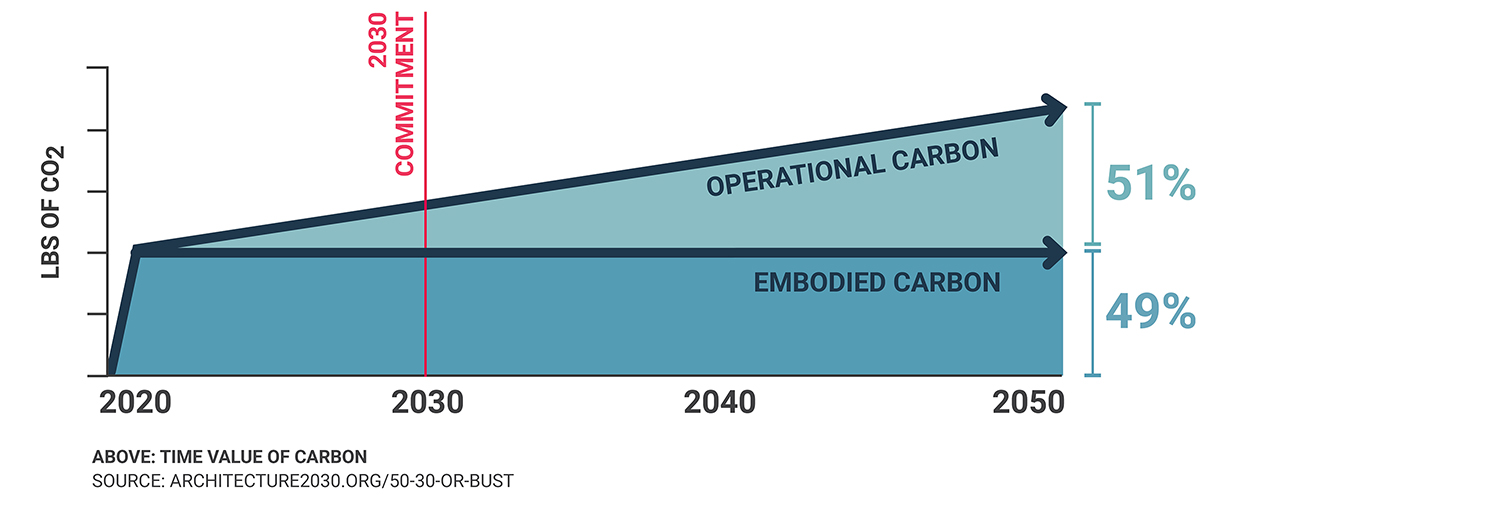

Within the design and construction industry, decades of research and development have gone into current energy efficiency standards. These standards generally focus on energy consumption and carbon emissions of buildings over the course of a building’s life, known as operational carbon. However, there is a significant portion of the carbon emission story that is missing which is known as embodied carbon.

Defined as “the greenhouse gas emissions arising from the manufacturing, transportation, installation, maintenance, and disposal of building materials,” embodied carbon emissions will be responsible for almost half of all new construction between now and 2050. Embodied carbon is locked into place as soon as the building is built and therefore, should be factored into the design and construction carbon reduction mindset.

Tracking and reducing embodied carbon emissions is new to most mainstream architectural design practices. For carbon data to be accurate, it often needs to come from manufacturers, and obtaining this data can sometimes be wrought with obstacles. Additionally, the new tools being used to test and quantify the carbon impacts of our designs depend on data that can typically be more generic than is helpful. The good news is that certified transparency documentation from product manufacturers is growing by the day, and we believe carbon tracking and reporting will soon become an industry standard practice.

WALKING OUR TALK

In 2009, Mahlum signed the AIA 2030 Commitment, pledging to prioritize energy performance in pursuit of carbon neutral buildings by the year 2030. When we moved from our previous Portland office to a new space in 2019, we had committed to designing a net zero embodied carbon office. We knew our new office had to live up to our commitment of creating a carbon neutral future so we could be more honest advocates to ourselves, and the clients we serve.

RENOVATION VS NEW CONSTRUCTION

Architect Carl Elefante coined the phrase, “the greenest building is… the one that is already built.” Keeping this in mind while searching for our new office location, Mahlum chose to move into 7,400 SF of what was once a metal stamping facility inside a 1939 warehouse building, located in Portland’s Central Eastside. Eventually renamed Custom Blocks Studio, the industrial aesthetic of exposed wood beams and steel structure inspired the team, seeing potential design benefits and carbon reduction opportunities.

Using the web-based tool Build Carbon Neutral, the team set out to establish an overall “embodied carbon budget” for the project. We began by calculating for a like-sized, new office construction project, which Build Carbon Neutral determined to be 195 metric tons of CO2. Wanting to understand what the carbon savings could be for a renovation (instead of building new), we cut the new construction number in half and landed on 97.5 metric tons of CO2 as our reduced embodied carbon budget target.

During design documentation and construction, we continually referenced that carbon budget target of 97.5 against subsequently more developed and robust Tally Whole Building Life Cycle Analysis analytics. A detailed embodied carbon analysis was performed, using the Tally software plug-in for Revit (our building information modeling program), allowing us to quantify life-cycle impacts of materials we designed for with material take-off quantities directly from the 3D Revit model.

DESIGN STRATEGIES

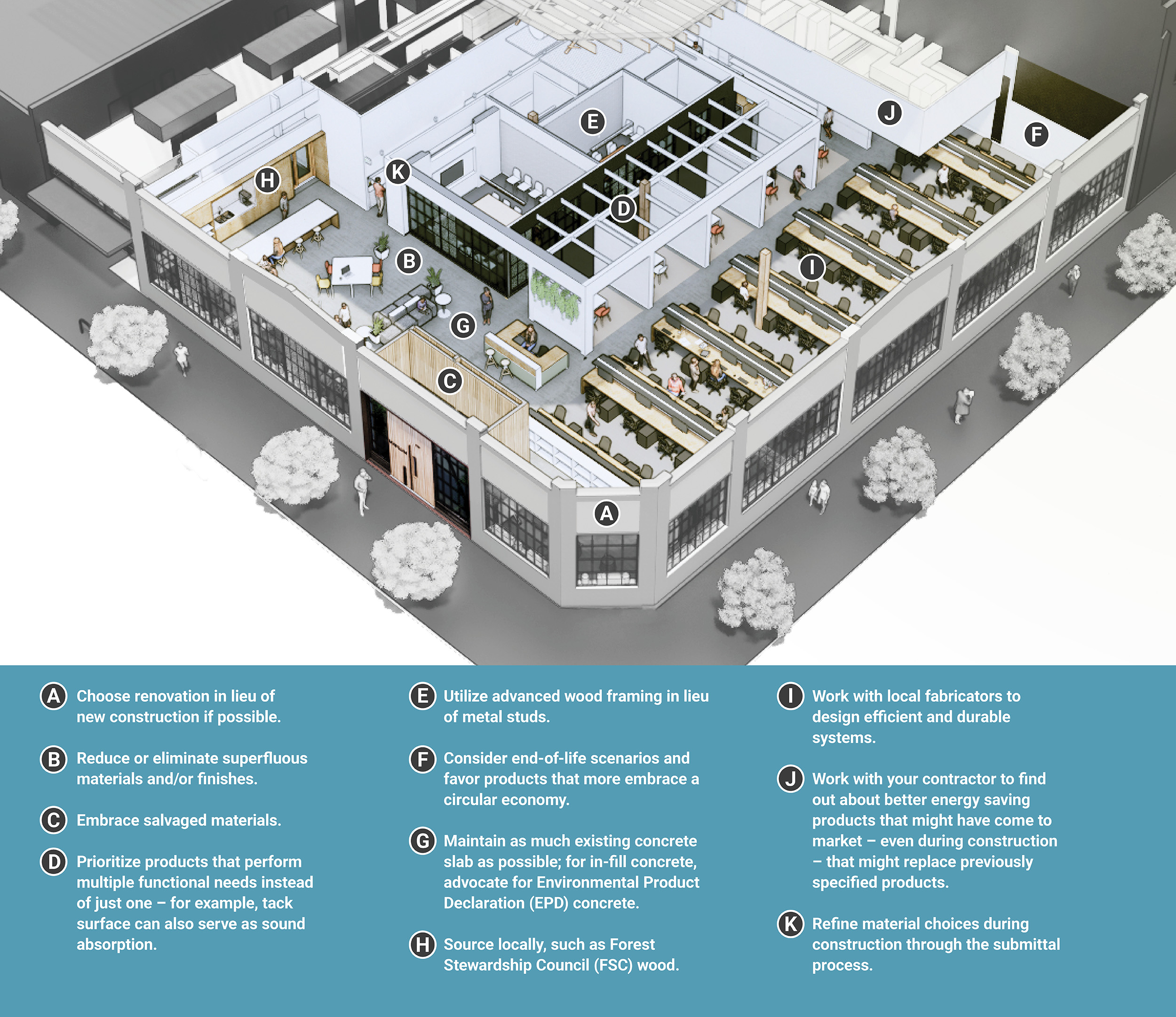

Throughout design and construction, the team endeavored to balance carbon reductions with other components such as material health and local sourcing. Overarching project goals were to: Use less stuff, use better stuff, and offset the rest.

The aerial rendering of our new office space below illustrates some of our strategies:

WHOLE BUILDING LIFE CYCLE ANALYSIS: CRADLE-TO-GRAVE

Taking a whole building approach to our analysis, the team evaluated the embodied carbon footprint over a 50-year span of the building’s life – known as a Life Cycle Assessment (LCA). We took a conservative approach to material replacement and “service life” assumptions, in part because we knew we weren’t able to quantify some of the materials within the casework, floor base, furniture, and/or equipment. Thus, the cradle-to-grave approach was chosen to reflect anticipated impacts of interior finishes more accurately over time.

Having spent over 20 years in our previous office, we were able to benchmark service life assumptions against our past operations and maintenance. We understand that LCA by its very nature is both imprecise and rapidly evolving, therefore our design team made conservative assumptions to ensure our accounting was representative of the finished product.

HOW WE GOT TO NET-ZERO EMBODIED CARBON

Research and analysis enabled us to interpret the impact our new office would have on global carbon emissions. Once the final numbers came in, we were thrilled to see all of our efforts paid off. Through rigorous design decisions, our original embodied carbon target budget of 97.5 metric tons was reduced to 74.4 metric tons of CO2 – the equivalent of 16 passenger vehicles driven for one year.

But we wanted to do more. Holding ourselves accountable for the 74.4 metric tons of CO2 we produced, we purchased equal amounts of carbon offsets with a donation to Terrapass. One of many organizations that fund large carbon emission drawdown projects, donating to Terrapass helps fund projects such as reforestation, renewable energy produced by wind power and methane capture at dairy farms, and landfill gas capture.

With the combination of rigorous design and the purchase of carbon offsets, the Custom Blocks Studio is now considered a net-zero embodied carbon office.

WORKING TOWARDS CLIMATE NEUTRALITY

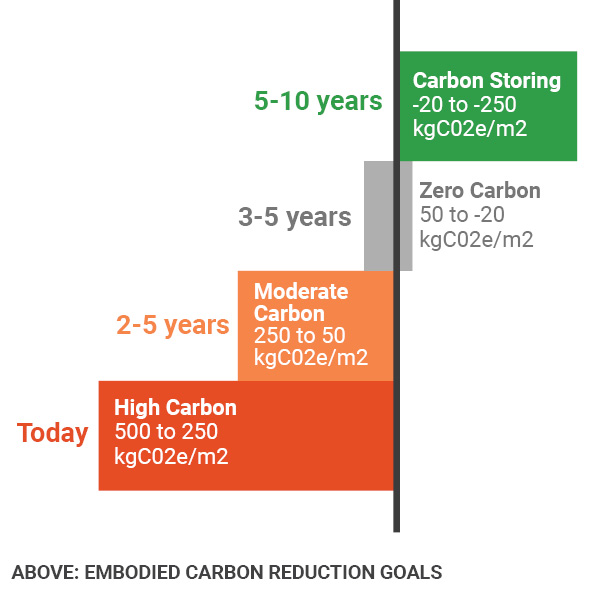

Building off the research that went into Custom Blocks Studio, Mahlum is now setting aggressive carbon reduction goals for all of its projects. We have begun a process that includes acquiring detailed project data, educating our staff to utilize available tools and resources, and building a database to compare and analyze all future projects to meet our AIA 2030 Commitment pledge. Firm wide benchmarks and tested carbon reduction strategies will inform our design process and ultimately help all of our clients decrease the carbon impact of their buildings to move towards a carbon neutral future.