by Joe Mayo

At Alki Elementary School, Mahlum was challenged with nearly doubling the floor area compared to the existing school to support increased enrollment on Seattle Public Schools’ (SPS) smallest school site in the district. Situated between a public park to the north, a steep hillside to the south, and public streets on either side, the only expansion option was up. Mass timber turned out to be the ideal material to meets the district’s needs.

The existing 1954/1967 school had long outgrown the community’s needs and students expressed resounding dislike for the building’s institutional, unwelcoming character and antiquated condition. While a full renovation was infeasible, the design did preserve and integrate the existing 1954-era gym and community center at the east end of the site into the new structure.

A NEW FOCUS ON EMBODIED CARBON

When the Alki Elementary School replacement project began, SPS had recently published the McLennan Report for SPS 2020, Sustainability Vision, Goals and Strategy which aligned with the District’s Natural Resource Conservation Policy and Green Resolution. This report elevated the International Living Future’s Living Building Challenge (LBC) as a certification system for the district.

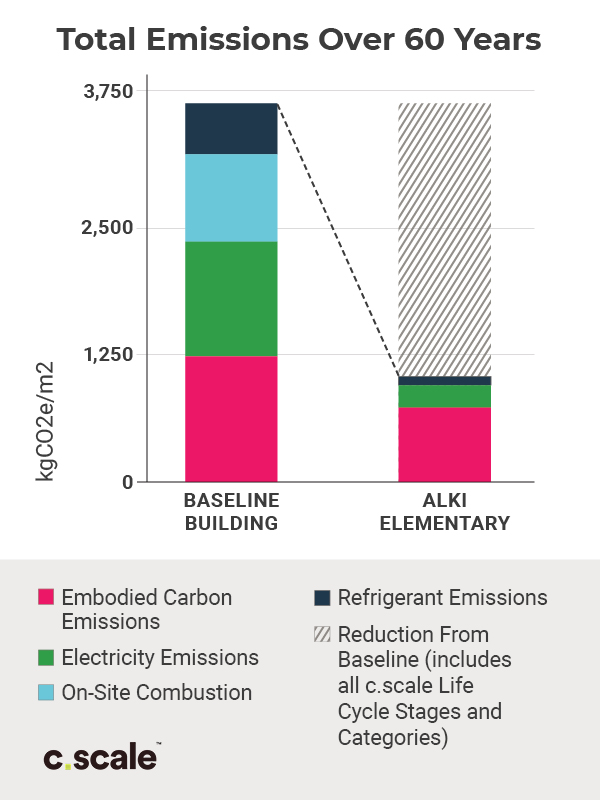

The LBC at the time mandated a minimum embodied carbon reduction of 20% below typical construction. To understand if such a reduction was possible for Alki Elementary, Mahlum used early carbon assessment tools like EPIC (now c.scale) to quantify big picture strategies for embodied carbon reductions. This early analysis suggested that a ~20% reduction in embodied carbon was possible by optimizing concrete mixes and using mass timber in lieu of structural steel.

MASS TIMBER AND EMBODIED CARBON REDUCTIONS

Mass timber is a way of building with large, solid, engineered timber elements that can replace steel and concrete. Based on successful mass timber projects and a recently completed Wood Innovation Grant studying mass timber and K-12 schools, Mahlum recommended the use of mass timber as a key strategy to reduce embodied carbon emissions, while also creating a warm, welcoming environment where students will thrive.

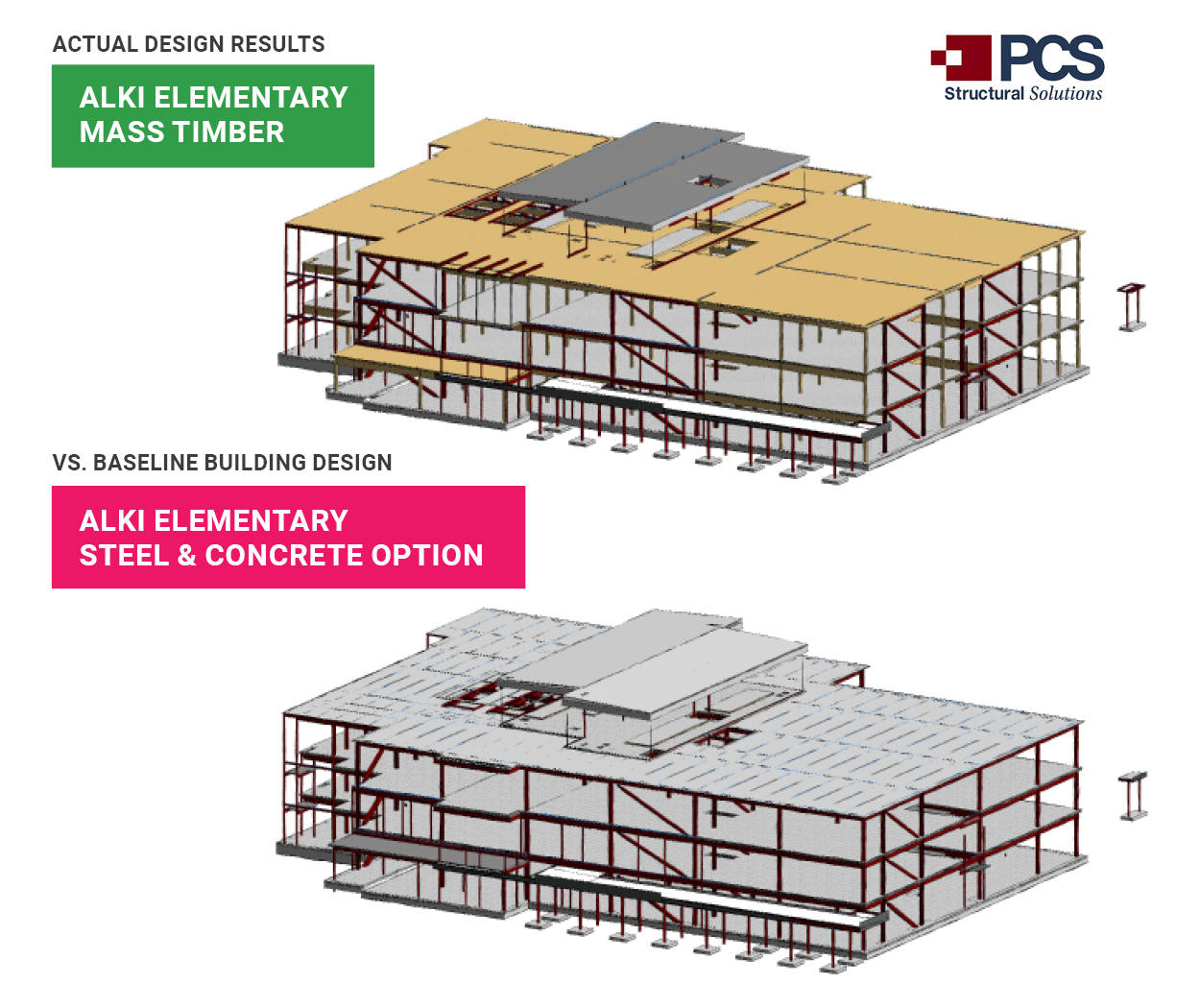

Building a three-story, 83,000 SF school from steel and concrete is typical, while using wood for this height and area is not. Mass timber design is significantly different from other construction types. Fortunately, along with Mahlum, the project structural engineer, PCS Structural Solutions, and General Contractor/Construction Manager, Cornerstone Construction, had experience with mass timber.

The team worked collaboratively during Schematic Design to determine the most efficient mass timber layout for the project. The team ultimately chose a typical timber grid of 11’ x 28’ and a three-ply cross-laminated timber (CLT) floor and roof deck. This approach minimizes intrusion of columns into learning spaces, while keeping the timber volume low and reducing costs. Compared to a baseline 30’ x 30’ grid using five-ply CLT panels, the approach taken for Alki Elementary reduced timber volume by over 30%.

The team used Tally, a Whole Building Lifecycle Assessment (WBLCA) tool to quantify embodied carbon reductions for structural elements. To demonstrate reductions, there must be a baseline building design to compare the actual design results. The baseline building in this case is an optimized structural steel school of the exact same size, area, height, and functional use – a typical design in the Pacific Northwest.

1 Biogenic carbon refers to carbon that is sequestered from the atmosphere during biomass growth.

Source: lifecycleinitiative.org

EMBODIED CARBON REDUCTION RESULTS

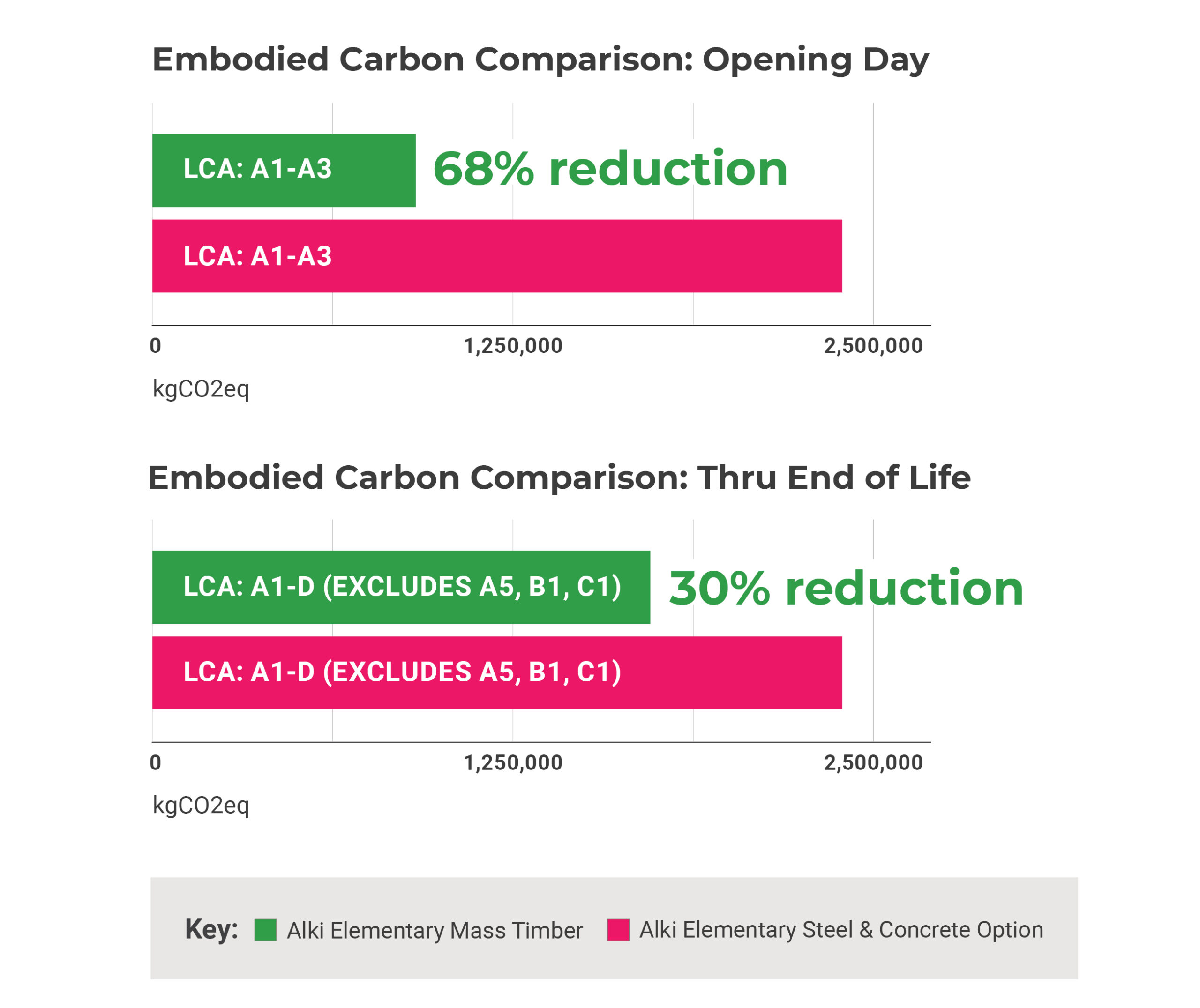

Confirming earlier assumptions, the Tally WBLCA results indicate that mass timber and optimized concrete reduced embodied carbon emissions significantly. Early Epic analysis estimated a 25% reduction, while Tally showed an even greater reduction of the actual design, at 30% lower global warming potential (GWP) for the mass timber option versus the baseline steel option.

The biggest decrease between the two options was in the product manufacturing stage (A1-A3). The mass timber option has a 68% reduction in GWP from the steel option for modules A1-A3. This substantial difference is due to lower manufacturing emissions of wood-based elements, as well as the fact that this LCA study accounts for the biogenic carbon1 stored in the mass timber elements. For Alki Elementary, all wood is sourced from sustainably managed forests (PEFC certified), so the design team felt comfortable accounting for biogenic carbon.

For the steel building option, the structure was the largest contributor to embodied carbon. In contrast, for the mass timber building, the interior finishes were the largest contributor to GWP. Gypsum wallboard was the single most impactful material in the mass timber building, followed by cementitious gypsum-based topping for the CLT floors and then carpet.

Utilizing Building Transparency’s EC3 tool, the specified carpet for the project represents a 62% reduction in GWP compared to the 2021 CLF baseline. The Gypsum Wall Board specified for the project represents a 36% reduction in GWP compared to the 2021 CLF baseline. These product-specific reductions are not accounted for in the Tally WBLCA results. Consequently, these product choices reduce Alki Elementary Schools’ overall carbon impact below what is reported by Tally.

SPS recognizes that measurement is critical for improvement. The analysis done here is to support that goal by demonstrating measured reductions in embodied carbon emissions through purposeful design, collaboration, and the use Life Cycle Assessment (LCA) tools. Reducing embodied carbon emissions in Alki Elementary School brings SPS one step closer to achieving their resource conservation goals.

—Peter Drucker, SPS’s McLennan Report for SPS 2020